What if your products could improve themselves in the field without human intervention? This is no longer speculative. It’s happening—now. In aerospace, MIT and NASA have already developed a shape-shifting wing that adjusts mid-flight to reduce fuel burn, emissions, and maintenance costs. In health care, biodegradable implants are being reconfigured inside the human body, minimizing surgeries and accelerating recovery.

This is the promise of four-dimensional (4D) printing. First introduced by MIT’s Skylar Tibbits, it combines intelligent materials, advanced engineering, and programmable design to create structures that evolve over time—responding to stimuli like heat, moisture, light, or magnetic fields. Unlike static 3D-printed objects, 4D-printed systems can adapt continuously, unlocking next-generation applications in manufacturing, infrastructure, and medicine.

Innovation is accelerating. In November 2024, researchers at the University of Colorado unveiled a breakthrough: multifunctional composites that can twist, curl, and morph using precise fibre orientation and patterning, pushing the boundaries of what materials can do. But unlocking the full potential of this technology depends on solving one crucial challenge—scaling the production of smart materials to make this transformative technology accessible worldwide.

4D printing gives early adopters a competitive edge in one of the most pivotal frontiers of innovation: smart materials. These adaptive systems reduce maintenance, accelerate production, and deliver products that evolve in real time—improving performance and durability in the field. The result isn’t just better engineering; it’s a strategic advantage. As industries race to boost resilience and sustainability, companies that embed responsiveness into their products will shape the future of markets. But this isn’t plug-and-play.

Based on our research and global work with innovation leaders, we’ve observed five key actions that set successful adopters apart: they assess market readiness, identify high-impact use cases, evaluate investment risks and returns, ensure their teams are equipped to execute, and monitor and iterate. We explore the dynamics and the required actions in detail below.

CRACKING THE CODE ON SMART MATERIALS

Smart materials are the engine of 4D printing’s adaptability. These materials respond to external stimuli by changing shape, properties, or behaviour. Examples include shape-memory polymers that return to a preset form when heated and hydrogels that expand or contract in response to water. We estimate the global smart materials market will reach US$150 billion by 2025.

Industry leaders, research institutions, and start-ups are racing to bring the technology to market. Autodesk is expanding its capabilities to support 4D printing, with its design software enabling simulations that predict material responses over time. This predictive approach is essential for developing durable, functional 4D-printed products. Boston-based Nervous System is working on adaptive materials that respond to body heat and motion, while MIT’s Self-Assembly Lab explores bio-inspired materials with self-healing capabilities.

Yet despite their potential, producing these materials at scale remains complex and expensive. Manufacturing often requires highly controlled environments, driving up production costs. There are concerns around durability and long-term performance, particularly under repeated environmental stress.

To overcome these barriers, leading research institutions and companies—like MIT and Dassault Systemes—are investing in next-generation materials that extend beyond the limits of traditional 3D printing. In January 2024, researchers at the University of Queensland introduced a 4D printing technique for soft robotics using liquid metal polymers that respond to infrared lasers, enabling robust structures with transformative capabilities. These collective efforts reflect a clear ambition: to make advanced, adaptive materials commercially viable and bring 4D printing into widespread industrial use.

SEIZING THE OPPORTUNITY

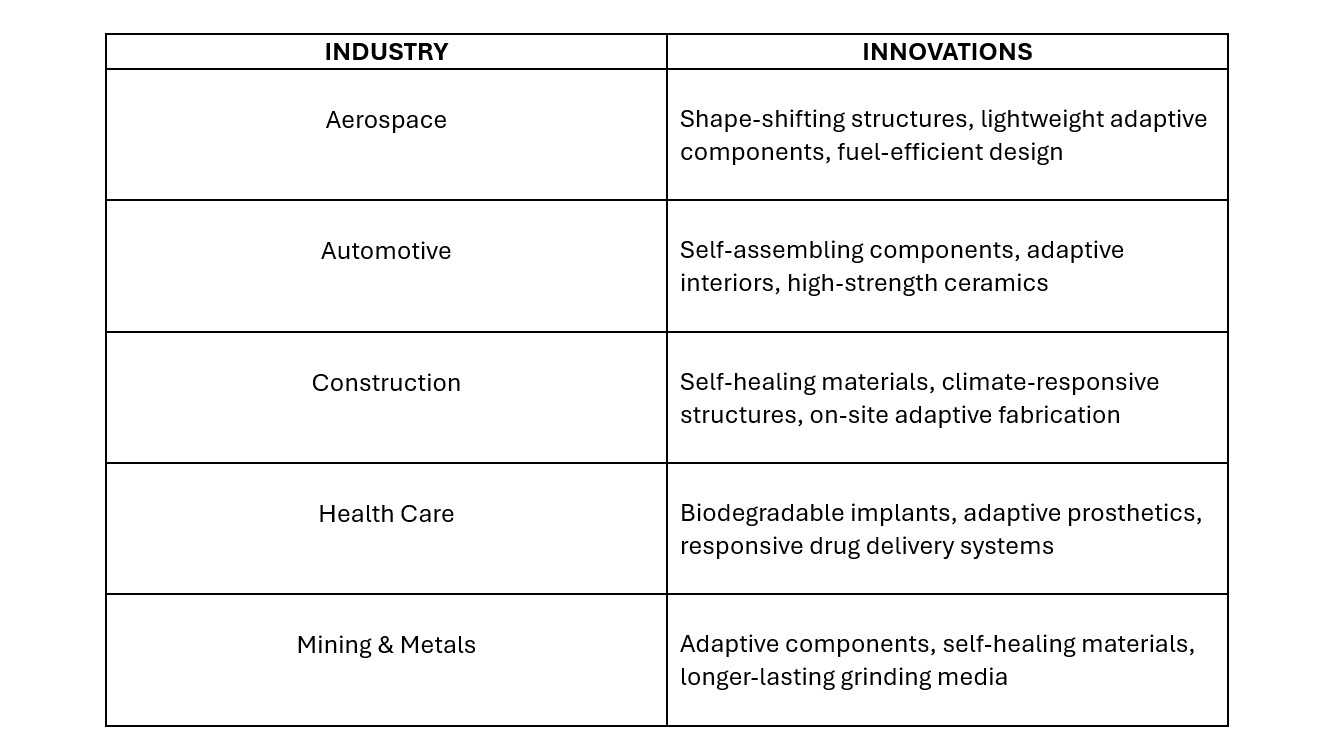

4D printing is set to play a significant role across industries. While applications vary, the common thread is adaptability—enabling smarter, more resilient systems tailored to dynamic environments.

MIT and NASA’s development of a flexible, shape-shifting airplane wing offers a glimpse into the future of adaptive aerospace design. This new design dynamically adjusts to different flight conditions, improving aerodynamics, reducing fuel consumption, and simplifying production and maintenance.

“Business leaders who invest early, engage with regulators, and explore strategic applications will be best positioned to lead.” ”

The health care sector is also emerging as a key beneficiary in areas such as tissue engineering and surgical implants. Children with congenital conditions, for example, could benefit from evolving devices that adjust as they age. 4D Biomaterials has launched 4D Design™, a suite of services to help medical device developers create advanced biodegradable devices using its proprietary 4Degra® polymer. 4D printing also opens the door to drug delivery systems that release medication in response to the patient’s biochemical signals, saving treatment time and side effects.

In automotive, 4D printing can ensure driver comfort and safety through its adaptive capabilities. For example, 4D-printed ceramics, created through direct printing using hydrogel dehydration, deliver high-strength components designed to endure extreme conditions, making them ideal for automotive applications. Smart materials can also let cars quickly change with road conditions.

4D printing offers significant potential in construction, driving sustainability, enhancing functionality, and enabling more flexible design. Buildings can self-adjust to temperature changes for optimal insulation or self-heal minor damage, reducing cost and extending lifespan. The technology can also enable on-site production of construction elements, reducing reliance on prefabricated components and allowing for greater adaptability to local conditions and design requirements.

4D printing offers transformative potential for the mining and metals industry with the promise of improving asset reliability, reducing costs, and addressing operational and environmental risks. In both fixed plants and mobile equipment, 4D-printed components could be used to adapt autonomously to changing operating and environmental conditions—enhancing equipment durability, minimizing maintenance-related change-outs, and ultimately lowering equipment life-cycle costs.

Other applications in mining and metals include integrating advanced 4D materials into engine components and heavy vehicle chassis; helping them withstand extreme temperatures; minimizing wear; and maintaining stability in harsh terrains, such as sub-zero or high-heat environments.

Smart materials can also be applied in tailings dams—for example, self-healing materials can be used to repair cracks that develop over time; similarly, adaptive structures could be used to change shape to address temperature changes, thereby enhancing structural adaptability and reducing safety and environmental risks.

In minerals processing, adaptive materials used in grinding and milling circuits can extend grinding media life, reducing replacement frequency, thereby increasing operating time, reducing operating costs, and improving productivity.

FIVE ACTION POINTS FOR BUSINESS LEADERS

- Assess market readiness: Business leaders must evaluate how 4D printing aligns with their industry’s goals. In health care and aerospace, the technology is nearing practical application, offering early adopters an edge. They should also check if their company has the right tools, skills, and mindset—and see if their peers are already investing to avoid falling behind and to reduce risk.

- Identify high-impact applications: Rather than exploring broadly, executives should prioritize high-value use cases with clear business and regulatory pathways. Health care, for example, offers strong early-mover advantage given its demand for personalization, cost efficiency, and minimally invasive solutions. Focusing on targeted areas like adaptive medical devices or responsive drug delivery can help accelerate commercialization while aligning with long-term care trends and regulatory frameworks.

- Evaluate investment risks and returns: A thorough cost–benefit analysis is essential, given the high costs and technical barriers. Partnering with start-ups, research institutions, and industry leaders can mitigate risks and accelerate innovation. While early adoption offers strategic advantages, executives must balance timing and investment to avoid committing before the technology fully matures.

- Ensure implementation readiness: A successful 4D printing strategy demands the right team, expertise, and infrastructure. Cross-functional collaborations among R&D, engineering, and business strategy teams are critical. Companies should invest in upskilling talent, hiring specialists in smart materials and 4D technologies, and identifying priority areas for investment. Clear performance metrics—such as cost savings, time-to-market, and customer satisfaction—will support data-driven course correction.

- Monitor and iterate: As 4D printing evolves, continuous monitoring of market trends, pilot projects, and competitor movements is critical. Feedback from early adopters can help refine execution and sustain momentum. Agility and responsiveness will be key to maximizing long-term impact.

EXPLORING THE NEXT FRONTIER

The trajectory of 4D printing over the next five to ten years will hinge on technological breakthroughs, industry adoption, and global collaboration. In the near term, health care and aerospace are expected to lead adoption, where adaptability and performance enhancements deliver immediate value. Both sectors will work closely with regulators to establish safety standards and build trust. Initial use cases will focus on high-value applications, with broader adoption likely as costs decrease.

Government–industry partnerships could accelerate progress, particularly in infrastructure, energy, and manufacturing—giving countries with strong 4D capabilities a strategic edge. While health care and aerospace may see early success, sectors like construction and consumer goods could face delays on regulatory and economic constraints.

Over time, 4D printing should reshape global trade and logistics through on-demand manufacturing and reduced inventory dependence. Realizing this potential will require coordinated effort across industry, government, and academia. Business leaders who invest early, engage with regulators, and explore strategic applications will be best positioned to lead. As material science advances and investments grow, 4D printing will move from promise to reality, redefining innovation, sustainability, and the future of manufacturing.

The authors would like to thank Sachin Kumar Chaudhary, Gargi Chakrabarty, Bijoy Anandoth Koyitti, Dhiraj Kumar Pandey, and Ganesh Patro for their contributions.

About Author

Seelan Naicker is a Managing Director, Accenture Australia and New Zealand – Industry X (Natural Resources). He focuses on Operational Excellence, Intelligent Asset Management, Capital Project Innovation, and Digital Business Systems.

Pradeep Roy is a Managing Director at Accenture and leads global Technology Research. He is most active on topics that explore the innovation potential of technology to drive business reinvention and enable socio-economic transformation to create 360-degree value.